Figure 1. Map of East Crete, Greece (Haggis and Mook 1993).

A large ceramic larnax from Mochlos, East-Crete, had to be conserved and reconstructed for the purpose of photography in a period of seven weeks for Prof. Soles, the director of the excavation. This project was started by the author at the Institute for Aegean Prehistory Study Center for East Crete (INSTAP-SCEC) around mid-October 1997 along with conservation work for four other excavations and an environmental monitoring of the archaeological storage areas in the basement of INSTAP-SCEC. Due to the deadline and the fragility of the clay material, the conservation methodology was adapted to the needs intrinsic to the larnax. The deadline was met, good quality photographs were produced and the larnax was found to be strong and stable enough to be moved within the Center when required. Works of this nature are possible thanks to the excellent new facilities available at the INSTAP-SCEC. Eventually, this larnax will be transported to the local archaeological museum in Siteia (East-Crete).

INSTAP-SCEC, conservation, large sized ceramics, Cretan Bronze Age larnax, plaster of Paris, photography, adaptable treatment methodology.

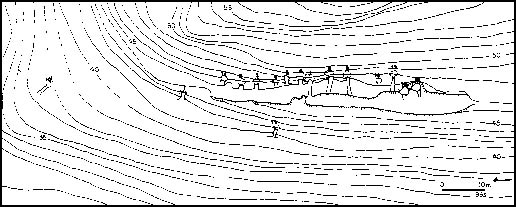

At the brand new Institute for Aegean Prehistory Study Center for East Crete (INSTAP-SCEC), based at Pacheia Ammos (Kavousi), a spacious and fully equipped laboratory for conservation has been operative since July 1997 (See Fig. 1).

Figure 1. Map of East Crete, Greece (Haggis and Mook 1993).

In this paper, the author chose to present one specific object that she was in charge of as a case study. Because of its large size, its state of preservation and the tight deadline, the ceramic "triglyph" larnax therefore necessitated a constant re-planning and re-thinking of the work to be carried out and offered several new insights for the author throughout its conservation process. This was possible thanks to the new facilities and the large work space of the conservation laboratory at INSTAP-SCEC.

The complete but broken "triglyph" larnax (nbr. C14) with lid was found in Mochlos in 1993

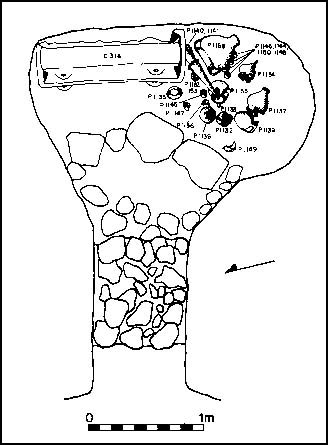

(directors of the Greek-American excavation: Prof. J. Soles and Prof. C. Davaras) in Tomb 15 which belonged to the Late Minoan III (LMIII) cemetery, situated on the Mochlos coast on the hill side behind the modern village (See Fig. 2).

Figure 2. Situation of the LMIII tombs at Mochlos (Soles and Davaras 1996).

Figure 3. Tomb 15 with larnax and grave goods (Soles and Davaras 1996).

Apart from three copper alloy objects, most grave goods were ceramic vessels, some of which were decorated, some of which were broken before they were deposited within the tomb (Soles and Davaras 1996: Soles 1999).

The aims of the project, as outlined by the field director, were straightforward: the conservator had to carry out the necessary work in order to render the larnax complete, stable and presentable for the purpose of good quality photographs and slides. This documentation had to be ready before the Christmas break of 1997 to be used by the director in a lecture at the annual meeting of the American Institute of Archaeology in Chicago in December 1997.

It was clear from the beginning that the main problems would arise from:

A summary on previous treatments of the larnax has been published elsewhere (Brysbaert 1998a: Brysbaert 1998b). Hundreds of sherds were stored in seven fruit crates for over 4 years in Mochlos. The sherds of the lid many of the smaller fragments of the larnax had ever been washed or desalinated. These were covered with dust, cobwebs and faeces of rodents. Some base fragments were extremely heavy and fragile and crumbled away. The largest base sherds formed one fourth of the base, weighing about 25 kilos, and the smallest were 1cm2.

The following are assumed to be the causes of damage to all areas of the base which weakened certain sherds beyond repair:

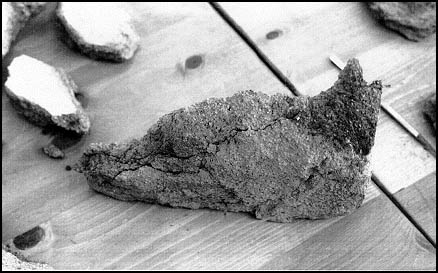

Figure 4. A corner fragment of the base showing heavy lamination (photograph: Ann Brysbaert).

Several sherds still showed the adhesives from previous treatment on their edges, forming thick crusts mixed with soil and small flakes of ceramic pulled off from other sherds. These adhesives must have been either too strong for the clay or a large amount of pressure had been exerted on some of the adhered sherds while in storage or the sherds were hastily pulled apart. Thick calcareous deposits were found on several break edges of sherds. This meant that those areas were already broken some time before the larnax was unearthed by pressure exerted on the object during burial. The larnax may have become distorted initially due to structural failure of the base. Many sherds of the larnax were cracked, laminated and warped, especially on corners and edges. No traces of paint were found anywhere on the larnax.

Solubility and consolidation tests were run before treatment to determine the best solvents and consolidant to use.

The aim of the solubility test was the succesful removal of the plentifully applied old adhesives. Nine small flakes of both adhesives were collected and put in glass beakers of pure solvents or solvent mixtures. One adhesive was yellow, slightly translucent to opaque while the other one was colourless transparent, containing trapped air bubbles. The author assumed the latter to be either a cellulose nitrate or an ethyl methacrylate co-polymer, for example Paraloid B72. The solubility results were poor for the yellow adhesive: a slight softening occured in acetone. However, the transparent adhesive partially dissolved in a mixture of acetone/ethanol forming a white precipitate but dissolved completely in acetone or toluene.

The aim of the consolidation test was to determine the strength of the ceramic body of the base and the other sherds. As described below, the use of stainless steel dowels was suggested for the reconstruction of the larnax. The nature of the clay, however, containing granite-diorite composite rock inclusions as a main filler (Haggis and Mook 1993), was hard but crumbly and would, according to the author, not withstand drilling for the dowels which could widen existing cracks. In order to test the strength of the clay, pins of various thickness were inserted into a few of the base sherds (consolidated and non-consolidated) and other sherds. Even in the consolidated base fragments, clay crumbled away and flaked off. A similar effect was produced in the other sherds with subsequent cracking of the clay.

All sherds which proved to be strong enough to withstand washing were cleaned of dust and soil under running tap water with brushes and sponges aiding the removal of harder accretions. The wet sherds were allowed to dry on several movable table tops which were also extremely handy for transport of the sherds for photography and on which to spread them out in order to start sorting the immense jigsaw puzzle (See Fig. 5).

Figure 5. The sherds spread out over movable table tops in the Center's courtyard (photograph: Ann Brysbaert).

The base sherds could not be treated similarly because any liquid would have turned them into mud. It was, therefore, decided to dry-brush the sherds and to use a small, portable vacuum cleaner with a fine gauze over the custom made, flexible nozzle to prevent loose flakes from disappearing into the dust bag. The vacuum cleaner, combined with the soft brushes, worked fast and efficiently with no ensueing damage. Many roots could easily be removed from the body sherds by washing only. In the base however, where the problem was much more acute, some of the exposed larger roots were cut away, leaving them partially in the clay matrix to act as a binder for the clay. The smaller roots had to be left in place for the same reason. Although tests had shown that acetone was successful in dissolving the old transparent adhesive, the application of swabs of acetone to the previously adhered joins produced only a slight softening of the adhesive. Since only the smaller sherds could be immersed in baths of acetone volunteers were shown how to apply acetone to soften the adhesive and then to remove it with dental tools and scalpels.

The calcareous deposits in cracks were removed with the aid of dental tools or a mini drill.

Due to the nature of most parts of the base and cracked corners and edges, it was decided that consolidation was required. Consolidation was divided in two stages:

Small base sherds were immersed in the low percentage Paraloid B72 solution for 24 hours until air bubbles ceased to form. Upon removal from the solution, the sherds were put in a closed container with acetone vapour to retard evaporation and to prevent the formation of a shiny surface.

Since the larger base sherds could not fit in the available tanks at the Center, they received localised consolidation with Paraloid B72. This was applied by pipette: a first application of 3-5% and where necessary, up to three more applications of the 7-10% solution. The same pipette application was carried out on many cracks until the matrix no longer absorbed the consolidant (See Fig. 6).

Figure 6. Consolidation of cracks: the consolidant applied with a pipette (photograph K. Barnard).

All edges of all sherds were given a protective consolidation with a 3% solution, applied once with a soft brush.

For reconstruction, the suggestion of using cellulose nitrate adhesive (Paterakis 1997) was followed because various conservators had worked sucessfully with this material on the reconstruction of large pithoi and because the process is much more reversible and far less destructive than the use of dowels. UHU Hart, a cellulose nitrate, was sucessfully used throughout the reconstruction phase and with the support of metal clamps, paper tape and plasticine during its setting.

During the reconstruction of the base, it was impossible to use all small fragments because there was not enough time to fit them in. Furthermore, even after consolidation, they would never provide the strength and support required for a base which had to support 150 kilos. It was thereupon decided to omit all small sherds from the reconstruction apart from the ones which had an aesthetic function on the inside surface of the base. This left about one fourth of the base open which was filled with coarse plaster of Paris, as the reconstruction proceded, until the base was completed. Fine white plaster of Paris was used to finish the visible surfaces.

During the reconstruction of the base, old sheets of dental wax were used to support the joins of the irregular surfaces. These wax sheets proved extremely useful because they can be folded in as many layers as required and still provide a minimum of flexibility. The lid was reconstructed in two halves which could not be joined due to warping. >From a practical point of view, this made the lid much easier to lift and transport. Once all gapfilling was completed, the plastered areas were inpainted with a mixture of powder pigments, water and Rowney's acrylic matt medium, to match the colour of the ceramic as closely as possible. Due to irregular firing of the clay, the colour had to be altered in several places to integrate the adjoining sherds. The inpainting was carried out on the interior and exterior of the larnax.

Prof. Soles needed black and white photographs and colour slides of the completed larnax for his lecture. Since there was no option of moving the larnax into the photography studio (due to space restriction) where everything is set up for sucessful documentation, background paper had to be cut out from large rolls, both in white and blue as required, and fit in place around the larnax in the conservation laboratory. A large piece of paper had to be hand held by two people in order to fill the film frame for the slides and photographs (See Fig. 7).

Figure 7. The photographic set-up with hand held backgrounds in the conservation laboratory (photograph: Ann Brysbaert).

It was decided to minimize the duration of the weight posed by the lid while resting on the larnax. This was accomplished by preparing three cameras with slides, colour print and black/white print film. During photography the first stage recorded all sides and parts of the object separately. In the second stage the smaller half of the lid was put in place on top of the larnax while photographs and slides were taken and while constantly inspecting the cracks. Finally, the other half of the lid was positioned next to the first half on the larnax while photographs and slides were taken at a high speed while two people changed backgrounds as was required (See Fig. 8).

Figure 8. The larnax after completion of treatment (photograph: Ann Brysbaert).

After a race against time to meet the deadline, it can be said that the project was completed successfully by meeting all requirements and producing good quality photographs and slides. The larnax withstood several transports to and from the storage area in the Center in the summer of 1998, thus revealing the true strength of the conserved object.

The presented work, carried out at the conservation laboratory of the INSTAP-SCEC, became a success because of its available space and new and plenty equipment.

It is clear to those who know the activities at the Center: archaeology and its linked disciplines have a future. For more information about this research Center, one can consult the newly launched website at: http://www.forthnet.gr/instapec. A biannual Newsletter 'Kendro' offers all recent news about ongoing projects and their people, lecture series and upcoming conferences (see for instance Kendro, vol. 2).

I would like to express my gratitude to Prof. J. Soles who allowed me to work on this project and to publish it. Since the author was the only conservator present at INSTAP-SCEC during the works on the larnax, assistance from T. Brogan, K. Barnard, E. Huffmann and N. Filson was very much appreciated, especially during the photography session. C. Mauzy helped with the illustrations for the publication and B. Tersago corrected the English text.

(1) The required temperature for sintering (between 700-800°C) of the clay material was probably not reached uniformly throughout the thickness of the base. Cracking, more probable due to the low firing temperature, may have allowed an easy access for roots to enter the base. Back to Text

BRYSBAERT A. 1998a. Conservation at the INSTAP-SCEC: the "Triglyph" Larnax from Mochlos. Glass and ceramics conservation. Newsletter of the ICOM-CC. Working group Glass, Ceramics and Related Materials 4: 7-9.

BRYSBAERT A. 1998b. Conservation and photography of the "Triglyph" larnax from Mochlos. INSTAP-SCEC Newsletter 1(2): 2-3.

BUYS S, OAKLEY V. 1993. The conservation and restoration of ceramics. Oxford/London: Butterworth-Heinemann.

DICKINSON O. 1994. The Aegean Bronze Age. Cambridge: C.U.P.

HAGGIS DC, MOOK MS. 1993. The Kavousi coarse wares: A Bronze Age chronology for survey in the Mirabello Area, East-Crete. American Journal of Archaeology 97: 265-293.

PATERAKIS A. 1997. pers. communication.

SOLES J., DAVARAS C. 1996. Excavations at Mochlos 1992-93. Hesperia 65(2): 176-230, plates 50-64.

SOLES J. 1999. The ritual "killing" of pottery and the discovery of a Mycenaean Telestas at Mochlos. Aegeum 20 (forthcoming).

Paraloid B72, Plaster of Paris, Rowney acrylic matt medium:

Supplier

Giorgos Pavlidis

Marathonomachon 1

104-41 Athens

Greece.

Manufacturer of Paraloid B72:

Rohm and Haas Ltd

Lennig House

Masons Ave.

Croydon

Surrey CR9 3NB

U.K.

Manufacturer of Rowney:

Daler Rowney

Bracknell

Berkshire

England.

Solvents, Paper tape:

Supplier

Plaisio (hardware shop)

K. Andrianou 59

72200 Ierapetra-Crete

Greece.

Manufacturer of solvents

Merck Ltd

Hunter Boulevard

Magna Park

Lutterworth

Leics LE17 4XN

U.K.

Manufacturer of paper tape

J.W. Bollom&Co Ltd

PO Box 78

Croydon Road

Beckenham

Kent BR3 4BL

U.K.

UHU Hart adhesive, metal clamps:

Supplier

any stationary shop in Crete.

Manufacturer of UHU Hart

UHU GmbH

77813 Bühl

Germany.

Dental wax sheets:

Supplier

P. Pretsios

Chalkokodili 15

104-32 Athens

Greece.

Manufacturer

Detreys Universal

Summit House

Moon Lane

Barnett

Herts

U.K.

Powder pigments:

Supplier

Abio conservation supplies

Ilidos 41

115-27 Ambelokipi

Athens

Greece.

Plasticine:

Supplier

toy shops on Crete, Greece.

Manufacturer

Harbutt's Plasticine

Peter Pan Playthings

Swindon

U.K.